Make New Entry, Make Followup Entry

User name Target Group

Log entry time 01:11:55 on January 08, 2009

Entry number 255082

Followups:

keyword=Target Activity Summary

*******************************************************

1. Checked the laser powers:

Original setting ::

Jlab :: I=36 A | T=25C | P=20.2 W

W&M :: I=35 A | T=26C | P=20.6 W

Rut :: I=34 A | T=20C | P=21.7 W

For 25 W check::::

Jlab :: I=40 A | T=25C | P=23.2 W

W&M :: I=40 A | T=26C | P=25 W

Rut :: I=40 A | T=20C | P=25.7 W

*******************************************************

2. Clean up optics

Replaced the fan cooling laser tips. Its fuse was broken. Fixed.

3. Turn on heater. Replace broken VARIAC fuse, heated oven to 230C.

4.1 Turn on vertical holding field with positive bigbite correction.

4.2 Connect Vertical Fiber; Low laser power confirm Vertical optics

check=== OK.

4.3 Full power vertical pumping.

Confirm spot on cell OK.

Confirm reflection near fiber tip OK.

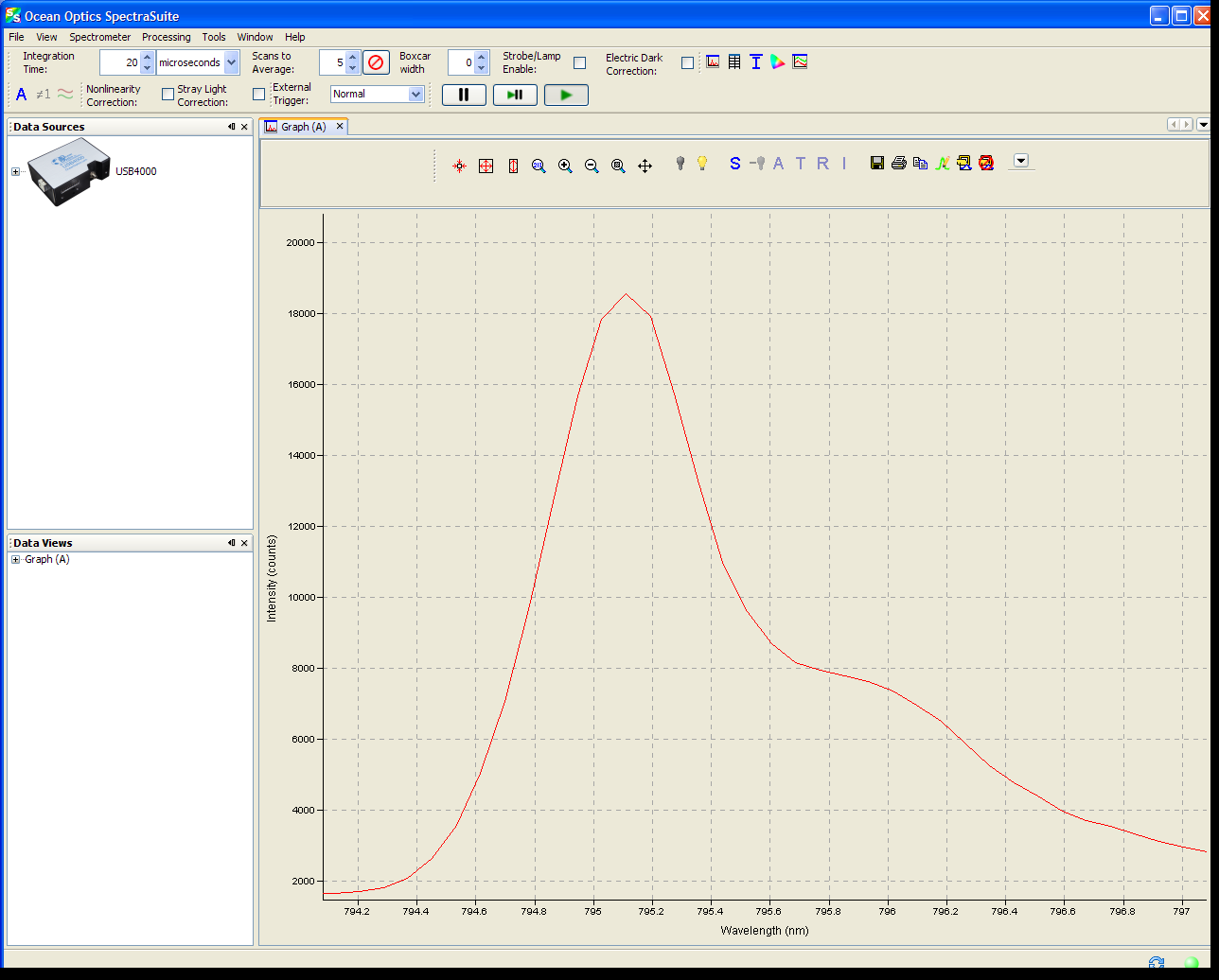

Confirm laser spectrum OK (fig 1).

D2 Diode output = -136mV

fiber connector temp. : 51C 64C 56C 52C 54C; tip: 64C

5.1 Connect fiber to Transverse Pumping; Holding Field rotate to Transverse

5.2 Confirm NMR signal acquisition with remain of little polarization:

http://spin.jlab.org/GenericLog/NMRField_07-01_23-10-51.html

5.3 Low laser power confirm Transverse optics OK.

5.4 Full power Transverse pumping.

Confirm spot on cell OK.

Confirm reflection near fiber tip OK.

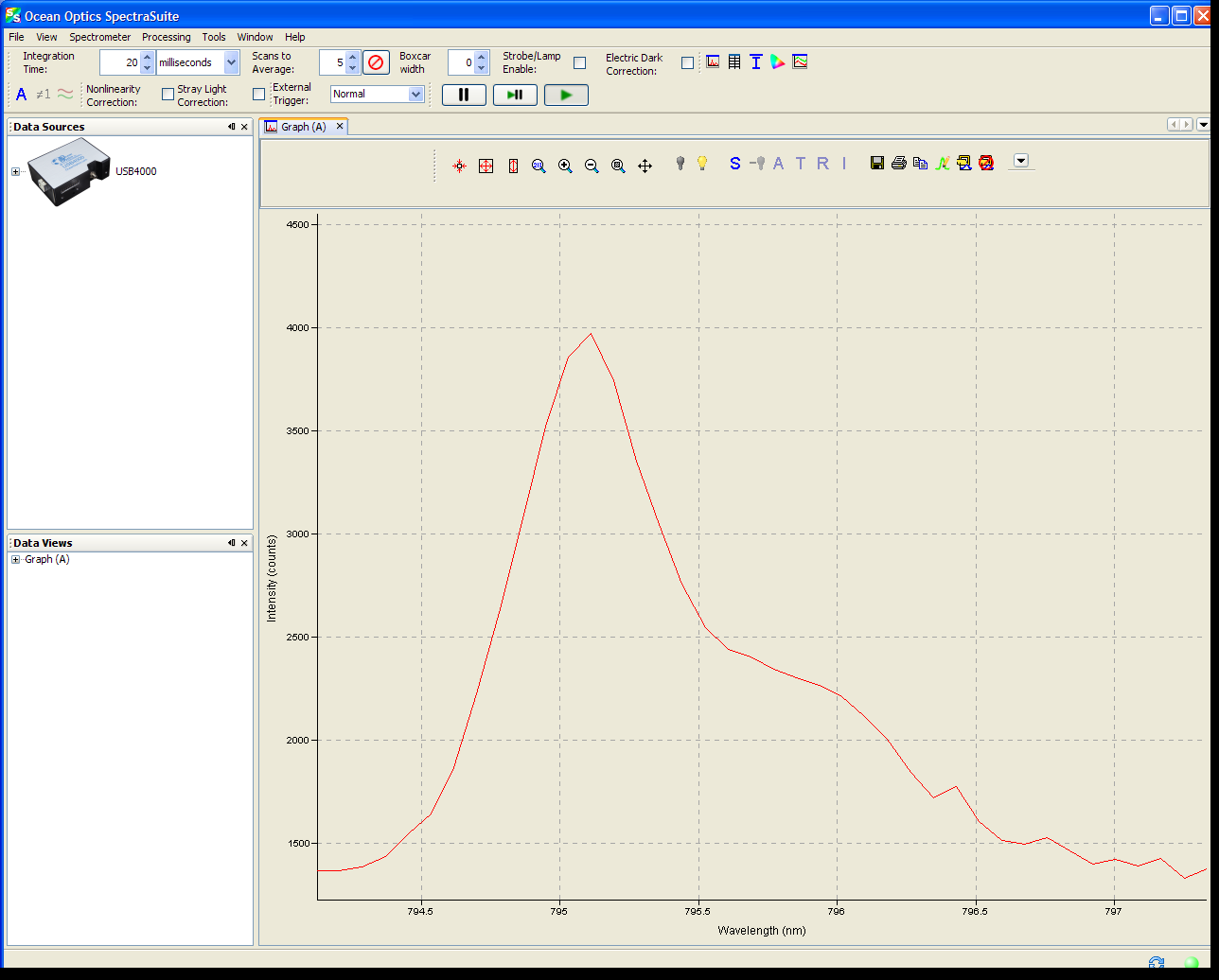

Confirm laser spectrum OK (fig 2).

D2 Diode output = -16mV; adjust fiber tip and get to -30mV

fiber connector temp. : 54C 52C 52C 61C 64C; tip: 60C

******************************************************************

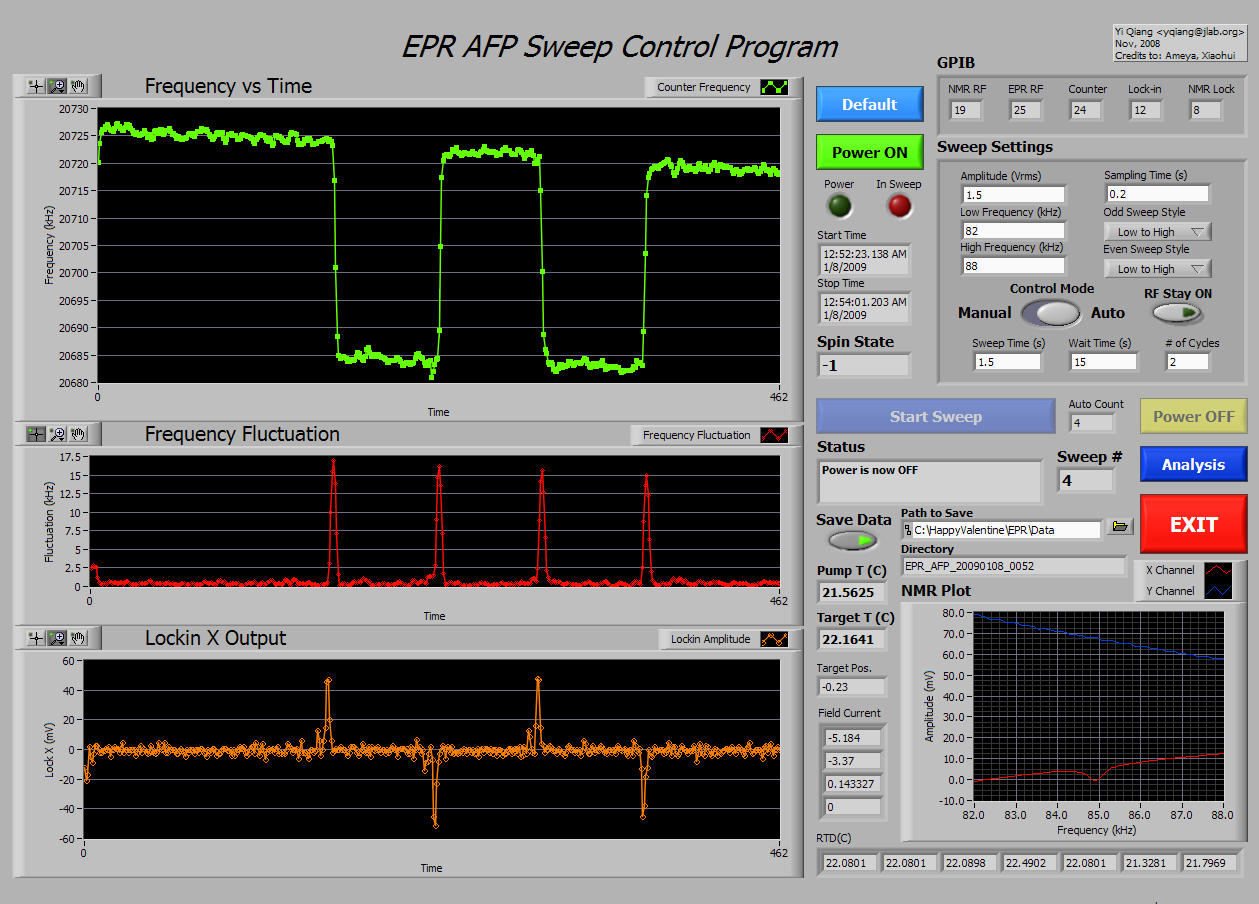

EPR @ Transverse - and - pumping

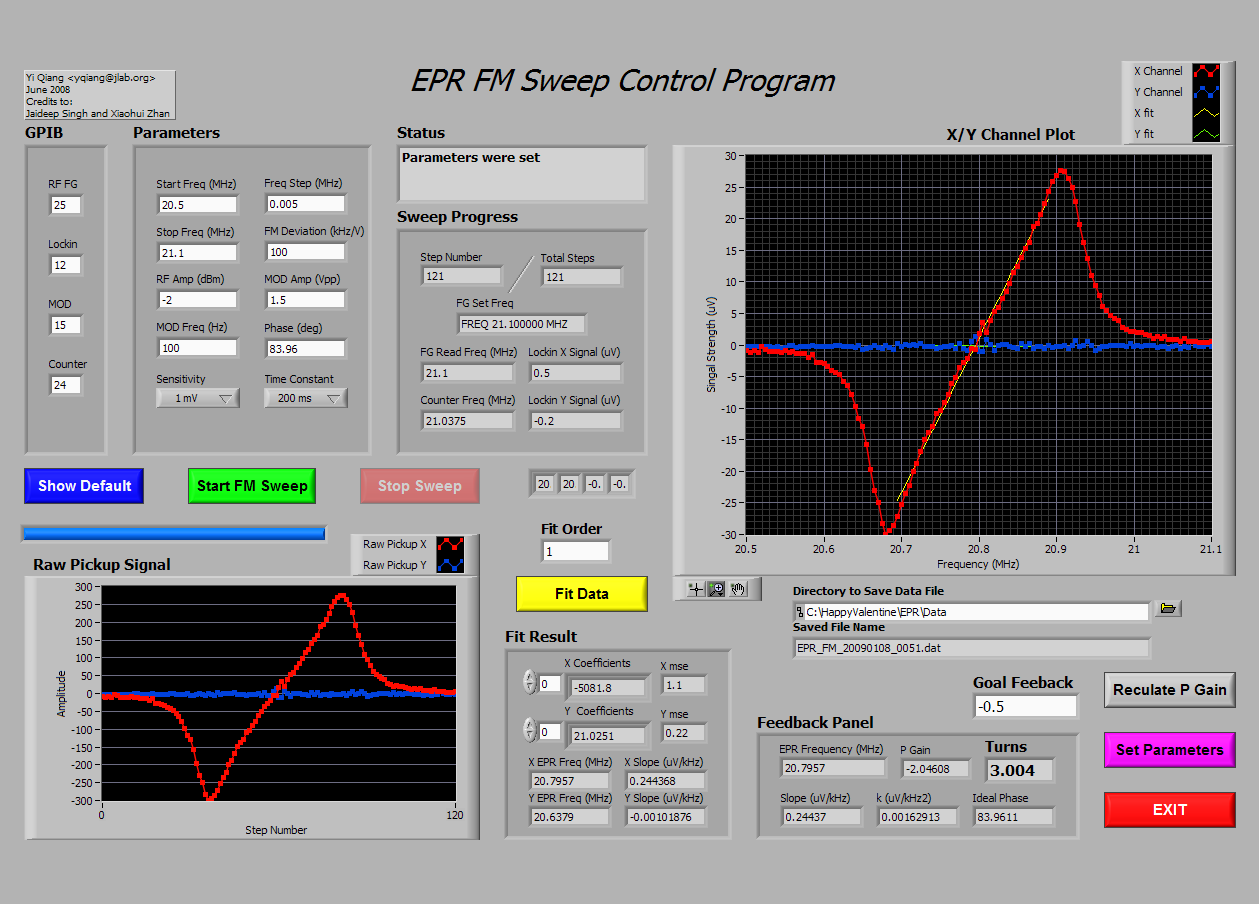

5.5 FM sweep {fig 3)

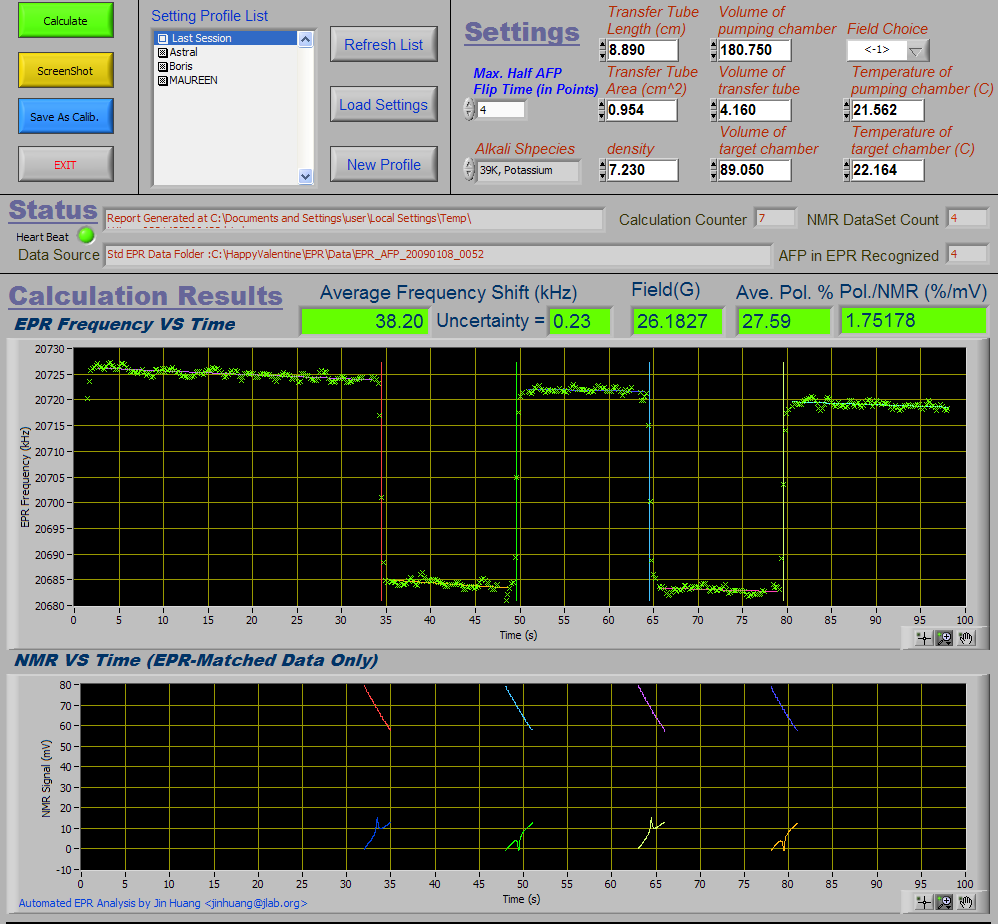

5.6 AFP ( fig 4)

5.6 Pol ( fig 5) . The polarization is 27.6% and the calibration constant

is 1.75.

There seems to be a field drift in the AFP spectrum which is probably

because of the closing of the target enclosure at that moment which in

turn might warm the holding field coils.

*******************************************************************

We keep the lasers ON at this hour and continue to do a spin up for the

new cell BRADY till tomorrow ( sometime ??).

NOTE ::: Our fiber test equipment ( the scope) has a broken focusing

knob. So either it needs to be replaced or something or we need to buy a

new one. Otherwise there is no way we can check the cleanness of the

fibers from now onwards.

A copy of this log entry has been emailed to: yqiang, jpchen

Figure 1: Vertical Spec @ 230C

Figure 2: Trans Spec @ 226C

Figure 3 : EPR FM

Figure 4 : EPR AFP

Figure 5 : EPR ANALYSIS