Technical Information Page

Green

Spot Technical Information

The Green Spot is designed for simplicity and reliability of operation.

The Green Spot features a "pop-off" lid for access to the lamp

reflector assembly, a big feature for intensive manufacturing line operations

where down-time maintenance must be kept to a minimum. This feature allows

the user to change lamp reflector assemblies in less than a minute.

The Green Spot uses an industry standard super-pressure mercury

100-watt lamp, mounted vertically, in a dichroic-coated elliptical

reflector to generate an intense, consistent, 5mm spot of

light in the UVA, UVB, UVC and visible ranges. This light

is delivered through a standard-length, 1000mm liquid-filled

light guide to any small application requiring a UV adhesive,

coating or ink. The optics system contains a quartz IR filter

that allows UV light to pass from the 300-480nm range. This

filter may be removed for UV chemistries that require activation

in the 200-300nm range or other visible ranges above the UV

range for visible cure chemistries.

The Green Spot is powered by a solid-state, power-regulated

power board designed to maintain 100 watts of continuous power

to the lamp. The power board is auto-sensing between 110VAC,

60hz and 220VAC, 50hz, for use both domestically and overseas.

The power input module is fused for 4 amps with an extra fuse

provided. The power board is cooled by two low-cfm fans to

provide a consistent operating environment and can operate

in a temperature range from 52°F to 100°F.

The Green Spot is in an attractive, all anodized aluminum (both inside

and out) enclosure to provide for clean-room operations as well as "cool

to the touch" running of the machine. It has vent holes around the

back of the external casing to allow proper ventilation and to prevent

cooling blockage.

The Green Spot also features a gravity-close shutter system for safety

to the operator and reduced risk of the shutter being stuck in the open

position. The solenoid offers reliable performance for 100% duty cycles

up to the default timer maximum of 99 seconds. This has been tested in

excess of 10,000 repetitions. An air-operated shutter system is also available.

The exposure timer can be activated by a PLC or initiated by an operator

with a foot switch by way of an RCA jack located on the back of the unit.

There is a switch in the back to allow the operator to use either the

timer for exact, repeatable time exposures, or manual exposure using the

foot switch.

Lamp intensity of the Green Spot starts in excess of 5000 mw and, over

the life of the lamp, degrades to 40% of initial output after 1000 lamp

hours. This is a standard characteristic of all arc lamps. Since most

UV chemistries need less than 1000 mw of UV to initiate proper chemical

reaction with the photo initiator, the 2000 mw of power toward the end

of lamp life is more than twice that needed to provide proper UV chemical

reaction.

The Green Spot uses a liquid-filled light guide to deliver UV and visible

light to the point source from the optics system. The liquid

is a saline solution and is non-toxic if broken. The light

guide is coated inside with a space-age material for maximum

reflectance of light entering and exiting the quartz lenses.

The manufacturer holds international patents. The Green Spot

has a lamp-hour meter that can be reset after each lamp reflector

change. UV Source warranties lamps for 200 hours, unconditionally.

From 200 to 500 hours, we will prorate usage on the difference

between 200 and 500 hours. In foreign countries, line conditioning

may be necessary to ensure proper input voltage and current

control and thus we cannot offer this warranty until this

is verified.

We have leading-edge, high-technology access to both engineering

and manufacturing methods as they relate to the UV industry.

Quality, reliability and service are a must with our flagship

product, the Green Spot. We are committed to customer satisfaction

and references are provided upon request. We are here to help

you with your UV spot-curing applications.

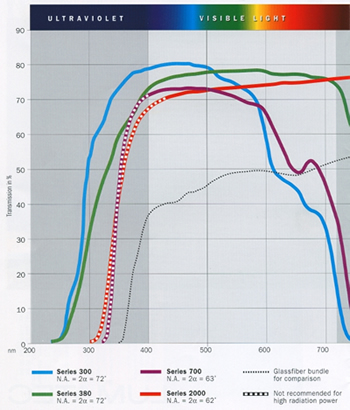

UV Transmission Chart

Light Guides

The standard light guide is designed to operate in the 320-500nm

range; however, we do sell a modified version that will operate

more efficiently in the UVB and UVC spectrum. (See Spectral

Chart above.)

The light guide degrades over time because of the UV exposure.

We recommend comparing used light guides to a new light guide

standard every 30-60 days. Significant reduction in UV transmittance

may occur and the UV intensity may be reduced by as much as

50% after 1 year of use depending on usage and exposure times.

The light guide is designed to bend slightly. This usually

means no more than a 90-degree bend over a 12" radius.

Reduction in UV output may occur.

The tips of the light guide are made of quartz and should be cleaned

with alcohol on a regular basis to eliminate dust, etc. If

UV glue is present on the tip, it will cure and become UV

blocking, significantly reducing UV output—as much as

100%.

If the IR filter on the Green Spot is damaged, broken or

clouded, the UV intensity output can be significantly less,

as much as 75%, and needs to be checked as part of regular

maintenance. Remove the light guide and look at the glass

filter with the machine off and turned upside down, and the

lid removed. If it appears bubbled, darkened or cracked, it

is a sign that it needs to be removed and replaced. Please

refer to the directions below.

IR Filter Replacement

Tools needed: Snap-ring pliers and a 3/32 bondus.

TURN OFF POWER TO UNIT AND UNPLUG FROM POWER SOURCE. Remove lid and

allow to cool for 5 minutes.

Please read all directions before attempting this. (See diagram

below)

1. Remove lamp reflector assembly completely and set aside. Be careful

not to touch any part of the glass lamp or glass reflector.

2. Remove 3 screws from around the light guide receptacle on the front

of the machine. This allows the optics system containing the

IR filter to be removed from the Green Spot. Be careful when

removing. The shutter will be free and will drop out. Note

the layout of the shutter position. This must be reassembled

exactly as is to ensure the shutter operates correctly when

reassembled. Make sure not to bend the shutter in any way.

Bending will render the shutter useless and a new one will

need to be ordered.

3. After removal of the optics system, you will be able to see the IR

filter at one end of the system. There are 2 more screws that hold the

square housing in place. Remove these 2 screws.

4. After removal of the square lamp reflector subassembly,

you will see the IR filter in the recessed end of the optics

system. Use snap-ring pliers to carefully remove the snap-ring

retainer. There are uv resistant coated washers holding the IR filter in

place. Make a note of their position if needed later for replacement

of the IR filter. Save these parts and store the filter in

a scratch-resistant container in case it is needed at a later

time. Be careful not to touch the IR filter with bare skin.

5. Reassemble the square lamp reflector subassembly with the optics system

and ensure the shutter is in correctly and sliding freely. The bottom

tab on the shutter that sticks out must be pointing towards the front

of the machine and resting on the top of the solenoid pin when inserted

back into the machine. The machine will not operate correctly if this

is not done.

6. Insert the optics system back into the machine and rescrew with the

3 original screws. There is a little play in the position of the optics

system when placing in the hole. Position the optics system as far to

the top of the machine as possible.

If you have any questions regarding this procedure, please call UV Source

at 1-800-783-1548.

|