An

Introduction to Thermoelectrics

©2001

Tellurex Corporation

1248 Hastings

Traverse City,

Michigan 49686 (231)947-0110

A Brief

History

Early 19th century scientists, Thomas

Seebeck and Jean Peltier, first discovered the phenomena that

are the basis for today's thermoelectric industry. Seebeck

found that if you placed a temperature gradient across the

junctions of two dissimilar conductors, electrical current

would flow. Peltier, on the other hand, learned that passing

current through two dissimilar electrical conductors, caused

heat to be either emitted or absorbed at the junction of the

materials. It was only after mid-20th Century advancements in

semiconductor technology, however, that practical applications

for thermoelectric devices became feasible. With modern

techniques, we can now produce thermoelectric “modules” that

deliver efficient solid state heat-pumping for both cooling

and heating; many of these units can also be used to generate

DC power in special circumstances (e.g., conversion of waste

heat). New and often elegant uses for thermoelectrics continue

to be developed each day.

A Closer

Look

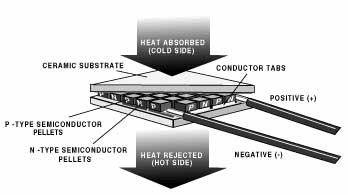

A typical thermoelectric module consists

of an array of Bismuth Telluride semiconductor pellets that

have been “doped” so that one type of charge carrier– either

positive or negative– carries the majority of current. The

pairs of P/N pellets are configured so that they are connected

electrically in series, but thermally in parallel. Metalized

ceramic substrates provide the platform for the pellets and

the small conductive tabs that connect them. The pellets, tabs

and substrates thus form a layered configuration. Module size

varies from less than 0.25" by 0.25" to approximately 2.0" by

2.0". Thermoelectric modules can function singularly or in

groups with either series, parallel, or series/parallel

electrical connections. Some applications use stacked

multi-stage modules.

Cooling, Heating: When DC

voltage is applied to the module, the positive and negative

charge carriers in the pellet array absorb heat energy from

one substrate surface and release it to the substrate at the

opposite side. The surface where heat energy is absorbed

becomes cold; the opposite surface where heat energy is

released, becomes hot. Using this simple approach to “heat

pumping”, thermoelectric technology is applied to many

widely-varied applications– small laser diode coolers,

portable refrigerators, scientific thermal conditioning,

liquid coolers, and beyond.

Power

Generation: Employing the effect which Seebeck

observed, thermoelectric power generators convert heat energy

to electricity. When a temperature gradient is created across

the thermoelectric device, a DC voltage develops across the

terminals. When a load is properly connected, electrical

current flows. Typical applications for this technology

include providing power for remote telecommunication,

navigation, and petroleum installations.

A

Comparison of Cooling Technologies

The flow of

heat with the charge carriers in a thermoelectric device, is

very similar to the way that compressed refrigerant transfers

heat in a mechanical system. The circulating fluids in the

compressor system carry heat from the thermal load to the

evaporator where the heat can be dissipated. With TE

technology, on the other hand, the circulating direct current

carries heat from the thermal load to some type of heat sink

which can effectively discharge the heat into the outside

environment.

Each individual thermoelectric system design

will have a unique capacity for pumping heat (in Watts or

BTU/hour) and this will be influenced by many factors. The

most important variables are ambient temperature, physical

& electrical characteristics of the thermoelectric

module(s) employed, and efficiency of the heat dissipation

system (i.e., sink). Typical thermoelectric applications will

pump heat loads ranging from several milliwatts to hundreds of

watts.

Thermoelectric

Benefits

The choice of a cooling

technology will depend heavily on the unique requirements of

any given application, however, thermoelectric (TE) coolers

offer several distinct advantages over other

technologies:

• TE coolers have no moving parts and,

therefore, need substantially less maintenance.

•

Life-testing has shown the capability of TE devices to exceed

100,000 hrs. of steady state operation.

• TE coolers

contain no chlorofluorocarbons or other materials which may

require periodic replenishment.

• Temperature control

to within fractions of a degree can be maintained using TE

devices and the appropriate support circuitry.

• TE

coolers function in environments that are too severe, too

sensitive, or too small for conventional

refrigeration.

• TE coolers are not

position-dependent.

• The direction of heat pumping in

a TE system is fully reversible. Changing the polarity of the

DC power supply causes heat to be pumped in the opposite

direction– a cooler can then become a heater!

Design Calculation Tutorial

Let's assume a solid-state electronic component

requires cooling to improve performance and reliability. The

component resides in an environment with a maximum ambient air

temperature of 50°C and dissipates 15 Watts. Cooling the

component to 25°C will improve performance and

reliability.

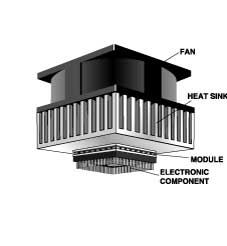

Our thermoelectric cooling system will have the

following physical characteristics:

the electronic

component will be in direct contact with cold side of the TE

cooler, and the heat sink and fan will be in direct contact

with hot side of the TE cooler.

The natural flow of

heat is always from hot to cold. When DC power is applied to

the thermoelectric module, the cold side becomes colder than

the electronic component, so heat flows naturally from the

component to the TE module.

The charge carriers in the

semiconductor material relocate the heat from the electronic

component to the heat sink. This causes the temperature of the

heat sink to rise. When the temperature of the heat sink

exceeds that of the surrounding air, heat will flow naturally

from the sink to the atmosphere.

System

Design

Our

known design values are:

Q = 15 Watt heat load from

electronic component

TA = 50°C maximum ambient air

temperature

TC = 25°C required temperature of

electronic component

Prior to using the performance

graphs to determine which TE cooler is appropriate for our

application, we must first identify the hot side temperature

(TH) and the resultant temperature differential across the

module (ΔT).

The hot side temperature will be equal to

the ambient temperature (TA) plus the rise in temperature

across the heat sink from dissipating the heat load (Q) and

the TE module power (V x I).

TH = TA + (V x I + Q) RQ

where RQ = thermal resistance of heat sink in C°

temperature rise per Watt dissipated. In this design, we will

keep the rise of the heat sink temperature to no more than

about 15°C above ambient. This would give us a TE module hot

side temperature of about 65°C.

TH = 50°C + 15°C =

65°C

The temperature differential across the module

can now be calculated as follows:

ΔT = TH - Tc = 65C -

25C = 40C

Module selection: The performance graphs for

each of the modules provide data for four different TH

conditions. The X axis along the lower part of the graphs

lists potential ΔT in C°. The Y axis at each side of the lower

graphs lists potential heat load in Watts. The diagonal lines

in the lower part of the graph identify the Q vs ΔT ratio for

several arbitrarily selected currents: I = 2.7A, 3.1A, 3.5A

and IMAX 3.9A.

Let's consider using a CZ1-1.0-127-1.27

Z-Max® module. First locate the graph for TH = 65°C [Fig. 4].

Then locate the heat load Q = 15W . Sight along a horizontal

line to the point that intersects with the diagonal line I =

2.7A. Sight down to determine ΔT = 45°C. This is 5°C greater

than the requirement and provides a margin of safety for

variation in assembly.

We can now determine the voltage

requirement by extending the vertical DT = 45°C line to the

upper part of the graph. At the intersection of I = 2.7A,

extend a horizontal line to the side of the graph where

voltage input is listed. The voltage requirement is 12VDC.

Heat sink selection: The values identified in the

preceding first pass analysis are used to assess overall

system feasibility. We want to qualify our assumption of 15°C

rise across heat sink.

The heat pumping capability of

the thermoelectric module is significantly influenced by the

efficiency of the heat sink. The hot side of the module must

interface with an efficient heat removal system to achieve

useful temperature differential across the module.

Natural convection, forced convection, and liquid

cooled are three of the most common types of heat sinks.

Thermal resistance varies among the different types and sizes

of sinks with natural convection being the least efficient and

liquid cooled the most efficient. The majority of

thermoelectric cooling applications use forced convection heat

sinks with thermal resistance values (RQ) ranging from 0.10°/W

to 0.5°/W.

Using values now known for TA V, I, and Q

we can solve for RQ to determine if it is reasonable:

RQ = (TH - TA)/(V x I +Q)=(65°C - 50°C)/(12V x 2.7I

+15W)

RQ = 0.32°C/W

Our proposed system using a

CZ1-1.0-127-1.27 Z-Max® module and a forced convection

sink/fan combination meets or exceeds the criteria for this

application.

Power Supply: Typical power sources for

thermoelectric coolers include batteries, automotive and

marine DC systems, AC/DC converters, and linear and switched

DC power supplies.

The

Thermoelectric “Sweet Spot”

Ninety per cent of all practical

applications for thermoelectric technology fall within a very

narrow range of operating conditions.

1.

Temperature differential (Delta T) between 30°C and

50°C

2. Thermoelectric module current draw (l) between

70% and 80% of IMAX, and

3.

Co-efficient of performance (COP) between 0.25 and

0.4.

Passive Load

In designing a

thermoelectric (TE) system, one of the most important

processes, is reaching an understanding of your thermal load.

Without this vital information, you cannot wisely choose the

best TE device or heat exchangers for the job. Each

thermoelectric system has a unique capacity for moving heat.

While it is possible to simply build up a system and then see

what it will do, it is usually far more prudent to optimize

your system for the desired outcomes. There is no better place

to start, than with a good, solid estimate of how much heat

must be removed from your thermal load to achieve the

performance objectives.

There are two components to

thermal load in TE systems: active and passive. Active load is

found whenever part of the load actually produces heat. An

example would be an electronic circuit in an enclosure; the

circuitry would dissipate wattage based on its voltage and

current requirements. Many TE applications don’t have an

active load (e.g., a food and beverage cooler) and this term

can be entirely discounted in these cases. Nearly all TE

systems, however, must cope with the passive portion. To

maintain a temperature difference between a thermal load and

the ambient environment, a certain amount of energy must be

continually moved into (for heating) or out of (for cooling)

the load. The rate at which this energy is moved (usually

expressed in watts), is the passive load.

One way to

conceptualize passive load, is to look at it like a leaky

boat. Water is continually streaming into the boat through all

of the various leaks (e.g., holes, faulty seals, etc.). The

more leakage there is, the faster the water will come into the

boat. Faced with this situation, if you wanted to maintain the

boat at a certain level in the water (and you couldn’t repair

the leaks), you would have to bale out the water at a certain

rate. If you bale too slowly, the boat will sink lower; if you

dump the water too quickly, you may rise above the desired

level (which may or may not be a problem). Ideally, of course,

you would repair the boat at the first opportunity so you

could minimize your future rate of baling.

With a TE

system, you are trying to keep your thermal load colder or

hotter than the ambient temperature. Unfortunately, no matter

how well you design your system, there will be some leaks.

There is no type of insulation with an infinite thermal

resistance, so some heat will pass right through your primary

line of defense. Furthermore, seals used to cope with the

inevitable holes (e.g., doors, TE engine pass-through, etc.),

will also be imperfect. Thus, in a cooling application, some

heat is going to leak into the thermal load from the ambient

environment. To paraphrase a popular sports expression, “You

can’t stop it, you can only try to contain it”. So you bale,

only this time you are baling out heat, and you’re not using a

bucket or a water pump, but a thermoelectric system—one which

is steadily pumping watts out of (or into for heating) the

thermal load.

So . . . how do you quantify your

passive load? First you have to identify the greatest

temperature difference (between your thermal load and the

ambient environment) that can occur. For instance, if you’re

cooling, what is the highest ambient temperature and how cold

will your load need to be in that circumstance. This is

generally your worst case. If you design your system so that

you’ll have enough cooling capacity in that worst case, you’ll

have more than enough potential for every other situation. The

worst-case difference between your ambient and load

temperatures, will be your 'Delta T' in the equations which

follow.

The Nature of Passive Load

The

transfer of heat from a load to the ambient environment, is

largely a function of two thermal processes—conduction and

convection. Conduction is the transfer of heat through matter

(insulation, structural components, seals, fasteners, etc.)

and is a function of the temperature difference (i.e., Delta

T) across the material, the physical dimensions, and the

thermal conductivity of the material (K). Convection is heat

transfer across the boundary layer of air at the surface of a

material. It is a function of the Delta T across the boundary

layer and the rate of air movement at the surface—the faster

the air movement, the greater the convection of

heat.

With a well-insulated thermal load (e.g., an

insulated enclosure), convection is a relatively

inconsequential component and you can often focus exclusively

on the conductive element. The following equation can be used

to estimate a purely conductive load:

where

Q

is the amount of heat

conducted (it can be expressed in either BTU/hour or watts,

although in the thermoelectric industry, most support

documentation is based on wattage);

ΔT

is the

temperature difference between the thermal load and the

ambient environment (in F° for BTU/hour calculations, in C°

for watts);

K

(Kappa) is the thermal conductivity of the

material expressed in either BTU/hour-feet-F° or

watts/meter-C°;

L

is the thickness of the material (in

feet for BTU/hour calculations, meters for watts); and

A

is the exposed surface area of the material (in

square feet for BTU/hour calculations, square meters for

watts).

If you want to include both the conductive and

convective components of the load, you can use this equation:

where

Q

is the amount of heat

conducted and convected (expressed in either BTU/hour or

watts);

K

(Kappa) is the thermal conductivity of the

material expressed in either BTU/hour-feet-F° or

watts/meter-C°;

h

is the heat transfer coefficient (in

still air, this ranges between 4-5 BTU/hour-feet2-F° or 23-28

watts/meter2-C°; in turbulent air, h falls in the range of

14-20 BTU/hour-feet2-F° or 85-113 watts/meter2-C°);

L

s

the thickness of the material (in feet for BTU/hour

calculations, meters for watts);

A

is the exposed

surface area of the material (in square feet for BTU/hour

calculations, square meters for watts); and

ΔT

is the

temperature difference between the thermal load and the

ambient environment (in F° for BTU/hour calculations, in C°

for watts).

Note that the result that you get for Q

with this equation will be lower than that obtained for the

formula based only upon conduction. This is because the

convection/conduction equation accounts for two sources of

thermal resistance to heat flow. With the calculation

reflecting a slightly greater series resistance to heat

leakage, it logically follows that fewer watts will be

indicated to compensate for passive load.

When you are

dealing with an uninsulated load, or an uninsulated portion of

one (e.g., a cold plate), then it becomes very important to

explore the convective part of thermal load. In these

situations, convection may offer the primary resistance to the

leakage of heat. Remember that in some situations (e.g., an

uninsulated enclosure), you will have air movement on both the

inside and outside; as a result, your Delta T will be split

between the two boundary layers (based on the relative

convectivity of each). As you will find in using the equation

below to estimate your convective load, without insulation,

you will need to pump a lot more wattage with your TE

system.

where

Q

is the amount of heat

convected (expressed in either BTU/hour or watts);

h

is

the heat transfer coefficient (in still air, this ranges

between 4-5 BTU/hour-feet2-F° or 23-28 watts/meter2-C°; in

turbulent air, h

falls in the range of 14-20

BTU/hour-feet2-F° or 85-113 watts/meter2-C°);

A

is the

exposed surface area of the material (in square feet for

BTU/hour calculations, square meters for watts); and

ΔTB

is the temperature difference across the boundary

layer at any exposed surfaces (in F° for BTU/hour

calculations, in C° for watts).

When dealing with

enclosures, you can also estimate your passive load

empirically once a prototype is built. Simply place a known

heat load inside (make sure that the enclosure can 'take the

heat'), then monitor the temperatures of the ambient and

enclosure interior. Once the Delta T between the inside and

ambient has stabilized, you can use the following equation to

determine the passive load:

where

Q

is the passive load,

expressed in watts;

TAMB

is the ambient temperature

after stabilization (in C°);

TENC

is the enclosure

temperature after stabilization (in C°);

ΔTDES

is the

desired temperature difference between the inside of the

enclosure and the ambient environment (in C°); and

P

is

the power dissipation within the heater employed for the test

(expressed in watts).

System

Assembly

Several

methods for installing thermoelectric modules have been

developed, including: mechanical clamping, epoxy bonding, and

direct solder bonding. The individual requirements of the

application will determine which method is most appropriate,

however, mechanical clamping is by far the most common.

Thermoelectric modules are relatively strong in

compression and weak in shear

Whichever method of

installation is used, it is important to avoid excessive

mechanical loading of the module.

Thermal resistance

occurs at each interface of an assembly and affects overall

system performance. In mechanically-clamped systems, the

recommended flatness of interface surfaces should be within

0.001". Even with this degree of flatness, interface materials

must be used to fill in the small thermal gaps; typical

choices include silicone-based thermal grease, graphite foil,

and thermally-conductive pads.

Special care must be taken

to insure that uniform pressure is applied during

installation. Recommended procedures for mechanical clamping

are illustrated in Figure 5.

Mechanical Clamping Method

The

following is a list of guidelines for using mechanical

clamping:

1. The mounting surfaces (between which

modules are to be clamped) should be flat to within 0.001".

2. Mounting and module surfaces should be carefully

cleaned to remove any grit, burrs, etc.

3. If more

than one module is to be used in the assembly, all modules

should be within 0.001" in height.

4. Coat the hot

side of the module with a thin layer of thermal grease, then

place it on the heat sink. Applying firm but even downward

pressure, move the module in clockwise/counter clockwise

motions. Do this until a slight resistance is felt and excess

thermal grease is squeezed out.

5. Coat the cold side

of the module with a thin film of thermal grease. Repeat the

process described in step 4.

6. Bolt the object to be

cooled and heat sink together using stainless steel fasteners

with washers or split type lockwashers. Insure an even

pressure across the module surface when tightening the screws.

Maximum recommended compression loading is 350 lbs. per sq.

inch of module surface. ©2001

Tellurex Corporation