Difference between revisions of "Protovec-1"

From Hall A Wiki

(→General Characteristics) |

(→Pickup Coils) |

||

| Line 12: | Line 12: | ||

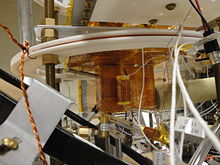

* Protovec-1 was fitted with three coils in addition to the normal pair used just outside the main oven of the UVa spin exchange optical pumping (SEOP) system. The large solenoid fitted around the transfer tube on the left in the image below is the ''pNMR coil'' which has 80 turns of 24 gauge insulated copper wire. The two solenoids on the target chamber are the '' TC coils'' which have 50 turns of 24 gauge insulated copper wire each. | * Protovec-1 was fitted with three coils in addition to the normal pair used just outside the main oven of the UVa spin exchange optical pumping (SEOP) system. The large solenoid fitted around the transfer tube on the left in the image below is the ''pNMR coil'' which has 80 turns of 24 gauge insulated copper wire. The two solenoids on the target chamber are the '' TC coils'' which have 50 turns of 24 gauge insulated copper wire each. | ||

{| | {| | ||

| − | | [[Image:Protovec-1_coils1.jpg|thumb|upright|220px|Wrapping | + | | [[Image:Protovec-1_coils1.jpg|thumb|upright|220px|Wrapping a 50-turn solenoid TC pickup coil on Protovec-1 target chamber.]] |

| − | | [[Image:Protovec-1_coils2.jpg|thumb|upright|220px|Protovec-1]] | + | | [[Image:Protovec-1_coils2.jpg|thumb|upright|220px|Wrapping an 80-turn solenoid pNMR coil on Protovec-1 1-inch bulb.]] |

| − | | [[Image:Protovec-1_coils3.jpg|thumb|upright|220px|Protovec-1]] | + | | [[Image:Protovec-1_coils3.jpg|thumb|upright|220px|View of three coils, a pNMR and two TC coils on Protovec-1.]] |

| − | | [[Image:Protovec-1_coils4.jpg|thumb|upright|220px|Protovec-1]] | + | | [[Image:Protovec-1_coils4.jpg|thumb|upright|220px|View of Protovec-1 installed in oven, pNMR coil on the left and two RTDs used to control and monitor the ''Convection Drive Oven''.]] |

|} | |} | ||

Revision as of 22:07, 1 November 2011

General Characteristics

- GE180 cell with 5:1 K/Rb alkali ratio and filled to 6.7amg 3He.

- Fabricated by Mike Souza mid-July 2011 at Princeton University. Requested Dimensions for Prototype Convection Cell.

- Filled by Al Tobias Sept 15, 2011 at the University of Virginia. The image below on the left shows the cell attached to the gas system and (sitting on the gas system table) stainless steel tubing that comes down and circles around in a rectangle and back up. This is our LHe Cold Trap for the purposes of purifiying our 3He gas before it goes into the cell. Both the LHe Cold Trap and the cell are immersed in LHe in our box dewar. The 3He gas is first sent thru the stainless steel loop then into the cell.

- Actual Dimensions of Protovec-1. Note about cell dimensions from Al Tobias -- "I regret that we forgot to measure the distance between the transfer tubes right under the pumping chamber. I remember making a rough measurement of the tubes, and found that they are indeed just under 2-inches apart (from central axis to central axis). I'll try to accurately measure this as soon as I have safe access to the cell. Let me know what distance below the pumping chamber your cell holder plate for the oven will attach to the cell's transfer tubes. Also note that I believe I kept the pull-off height less than 1.5" long. This dimension is hard to measure since the pumping chamber is not really spherical. So I measured from the bottom of the pumping chamber to the top of the pull-off."

Pickup Coils

- Protovec-1 was fitted with three coils in addition to the normal pair used just outside the main oven of the UVa spin exchange optical pumping (SEOP) system. The large solenoid fitted around the transfer tube on the left in the image below is the pNMR coil which has 80 turns of 24 gauge insulated copper wire. The two solenoids on the target chamber are the TC coils which have 50 turns of 24 gauge insulated copper wire each.

Convection Drive Oven

- Protovec-1 was installed in transverse mode into the UVa SEOP oven. The Convection Drive Oven is of force hot air type, much the same as the main SEOP oven. The drive oven was constructed with CaSi board wrapped in Kapton tape. It has dimensions 4.5" H x 2.0" W x 5.5" D looking into the oven along the pumping laser beam path.