Procedure for Longitudinal 3He Elastic Measurement

Contents

Procedure

- Move the target to 3He position and wait until the target temperature gets stabilized.

- Do a NMR Frequency Sweep with Lasers ON in Vertical - direction and record the polarization.

- Turn OFF lasers.

- Rotate the field to Longitudinal (+ for first part and - for the second part).

- Wait until the target temperature gets stabilized to start CODA runs

- After the 4 hours running, rotate the field back to Vertical -.

- Turn ON lasers and wait until the target temperature gets stabilized.

- Do a NMR Frequency Sweep and record the polarization.

NMR Fequency Sweep Procedure

Never do sweep in position other than 3He and Pickup !!! Never do sweep during target movement !!! Never do sweep when temperature not stable !!! Never do sweep during production !!!

Before an NMR Frequency Sweep, check NMR RF coils, pickup coils and Lock-in trigger connections:

- The connectors for pickup coils are in the front side of the rack ;

- The connector for RF coil is in the back side of the rack ;

- The connector for Lock-in trigger is in the back side of the top NMR lock-in amplifier and make sure it's connected to the cable labeled with Frequency Sweep;

- The pickup coil cable connected to Upstream is labeled as Target 2;

- The pickup coil cable connected to downstream is labeled as Target 3;

- For Vertical direction, use

* Transverse pickup(Target 4) pickup coil for pumping chamber; * Longitudinal RF(Target 5) RF coil;

- For Longitudinal direction, use

* Transverse pickup(Target 4) pickup coil for pumping chamber; * Vertical RF(Target 6) RF coil;

Make sure the EPICS Daemon is runing, it can be found in:

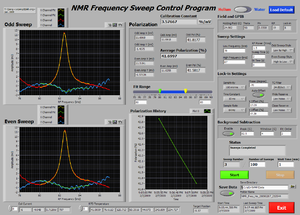

C:\AyeD\VI\Spin Flip\EPICS Daemon.viThen open the program for NMR frequency sweep:

C:\AyeD\VI\NMR\NMR_Fequency_v7.vi

do the following steps:

- Run the program if it's not currently running;

- Select Helium;

- Press Load Default button;

- Make sure that Holding Field is about 25 Gauss, Sweep range is 77 to 85 kHz;

- Make sure that Save Data is pushed;

- Set Number of Sweeps to 1;

- Press Start button to start the sweep;

- The program can be stopped anytime by hitting the Stop button, other wise it will automatically stop after desired sweeps finished;

- Once all sweeps completed, a report screen with a screen shot will automatically popped out, please save the screen shot into the picture folder on desktop;

- Do not EXIT the program because it's monitoring the oven temperature.

- Post a Halog entry with the descriptions of

* Field direction * Which RF coil * Which pumping chamber pickup coil * At what target position * Taking time * Target Polarization * the screen shot you just saved.

COMET Laser Control

Each of the COMET Laser Control is divided into to parts representing two controllers we're using at the same time as you see in the snapshot.

- The top one is for the Diode Driver, which is the power supply of the laser diode and controls the current.

- The buttom one is for the Temperature Controller, which is controlling the diode temperature so that the wavelength of the output laser is stablized.

Diode Driver

The control of the diode driver has three sections:

Status

Always turn ON the temperature before turn ON the laser diode

There are four clickable options and three indicators

- Indicator Comm: Shows the communication status, it should stay green when the communication to the device is good

- Options Disable and Enable: Used to enable or disable the laser. The check marks will not be updated automatically, so some time it's may not be in the right place.

- Second Indicator: Broken... and always in red....

- Options Remote and Local: Used to switch between remote and local mode. The GUI can only read back status and send commends in Remote mode.

- Third Indicator: Green means Remote mode and Yellow means Local mode.

Current

The unit in this section is wrong, and should be A instead of mW

- Photo Diode Current: Current read back of the laser diode.

- Set Current: Only editable place in this section. One can change the laser current by putting new values into the window then hitting enter key.

- Current SetPoint: Read back the current setpoint. If one changed the current, this read back value is expected to be changed if the change is succeeded.

Condition

The section shows all the status bit, only three of them need to be paid attention

Only Output ON/OFF State is expected to be ON during normal condition.

Any other status bit should be off during production. Here I list some common problems

- Output Outside Tolerance: This is on when the laser current is ramping up or far away from the setpoint.

- Interlock Disabled: When the interlock is broken for some reason.

Temperature Controller

The control of the temperature controller is very similar to the diode driver with some minor changes:

Status

For the diode safety, always keep temperature controller ON

This section is exactly the same as the Diode Driver.

Temperature

This section is the same as the Current section of Diode Driver.

Condition

This section is the same as the Diode Driver and only the Output ON should be on during normal condition.

Current/Voltage Limit are sometimes ON when the controller is adjusting the temperature and should NOT be treated as a problem.

Field Rotation GUI

The field rotation code is saved at:C:\AyeD\VI\Field Rotation\3D_Rotation_v4.vi

Before rotate the field, make sure the following condition satisfied:

- Target ladder is not moving;

- Lasers are OFF;

- No other target events are running (EPR, NMR, current calibration and etc.)

- Because the timing is controlled softwarely by the computer, so close all other unnecessary programs and windows

To rotate the field to a desired direction:

- Find the code and run;

- Check current magnetic field direction: a green line in the figure;

- In the Destination panel, select the desired direction;

- Hit Load button. The desired direction will be marked in red;

- Check the field strength input and set it to 25 Gauss;

- Check the rotation speed is 1 degrees per step;

- Press Start Rotation/Ramping button, then hit Go ahead button;

- Wait until rotation finishes. If success, both the Field Match and Angle Match lights are ON.

- Make a Halog entry.

If wrong direction is selected, do not panic because the field rotation/ramping can be stopped by pressing the Emergency STOP button. Please go to correct direction afterward.