Difference between revisions of "Target Lab Main"

From Hall A Wiki

(→Oven Test) |

(→TODO List) |

||

| Line 13: | Line 13: | ||

** {{pass |Air flow test}} | ** {{pass |Air flow test}} | ||

** {{pass |Heater test}} | ** {{pass |Heater test}} | ||

| − | ** Setup RTD reader | + | ** {{pass |Setup RTD reader}} |

| − | ** Setup spectrometer | + | ** {{pass |Setup spectrometer}} |

** Install He3 cell | ** Install He3 cell | ||

** Install target chamber pickup coils | ** Install target chamber pickup coils | ||

| Line 22: | Line 22: | ||

** {{pass |Cleaning optics stuff}} | ** {{pass |Cleaning optics stuff}} | ||

** {{pass |[[Target_Lab_Main#1.2F4-Wave_Plate_Calibration | Q-wave plate calibration]]}} | ** {{pass |[[Target_Lab_Main#1.2F4-Wave_Plate_Calibration | Q-wave plate calibration]]}} | ||

| − | ** Install optics | + | ** {{pass |Install optics}} |

| − | ** low power alignment | + | ** {{pass |low power alignment}} |

** High power alignment | ** High power alignment | ||

** Optical Pumping Operational | ** Optical Pumping Operational | ||

Revision as of 15:02, 1 April 2010

This is main page for work in EEL target lab since 2010.

Contents

Experiment Log

TODO List

- Clean and organize target lab

- Around He3 Cell

- Oven positioning

- Holding field hardware

- Air flow test

- Heater test

- Setup RTD reader

- Setup spectrometer

- Install He3 cell

- Install target chamber pickup coils

- Attach RTDs

- Laser Subsystem

- Cleaning optics stuff

- Q-wave plate calibration

- Install optics

- low power alignment

- High power alignment

- Optical Pumping Operational

- NMR Polarimetery

- NMR RF Delivery

- Pumping chamber pick up coil setup

- Target chamber pick up coil setup

- pick up coil alignment

- NMR code

- NMR Operational

- water NMR

- EPR Polarimetery

- EPR RF Delivery

- D2 light collection

- EPR code

- EPR line shape

- EPR frequency lock

- EPR Operational

Records

Oven Test

Heater Test

Oven is tested on Mar 24, 2010 without cell. Gas flow is 5~6 in mechanical meter, 508 on digital meter.

- If turn on the constant heater only (set temperature -> 20C), heater temp reached 212C, oven reached 154C

Air Flow meter Calibration @ Mar 9, 2010

Air flow meter in oven control chassis is cross calibrated with mechanical air flow meter at target.

| Mechanical Flow Meter | Digital Flow Meter |

|---|---|

| 1 | 260 |

| 3 | 390 |

| 5 | 490 |

| 7 | 600 |

Alarm 4 is set at 280.

1/4-Wave Plate Calibration

3/15/2010

COMET LASER (JLAB #1)

half power - 12.2 W

I=30A T=20C

| 1/4-Wave Plate | Angle | Residual Power |

|---|---|---|

| #101 | 286° | Reference |

| #102 | 214° | 272 mW |

| #19 | 127° | 256 mW |

| #16 | 330° | 185 mW |

| #21 | 240° | 165 mW |

| #2 | 76° | 55 mW |

| #25 | 120° | 164 mW |

| #20 | 225° | 114 mW |

Also #17 and #7 are identified as half wave plates.

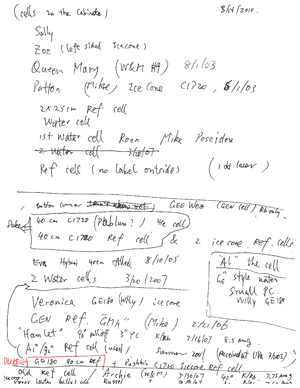

Cell Inventory

Manuals

Old Hall Setting Documentations

- Basic He3 Target Information

- He3 Target Logbook

- Target Ladder diagram

- Complete System Diagram

- Target preliminary survey of ladder before change ( scheduled to be done on monday November 11th 2008)

- Strip Charts

- Special Procedure For Moving Target

- Procedure for Longitudinal 3He Elastic Measurement

- Target Slow Control

- Online Spin Flip

Check Lists

- eed Target Operator Check List

- Target Operator Check List

- d2n Target Operator Check List

- Hall Access Check List

- Target Enclosure Work Checklist